Industrial Panel PC

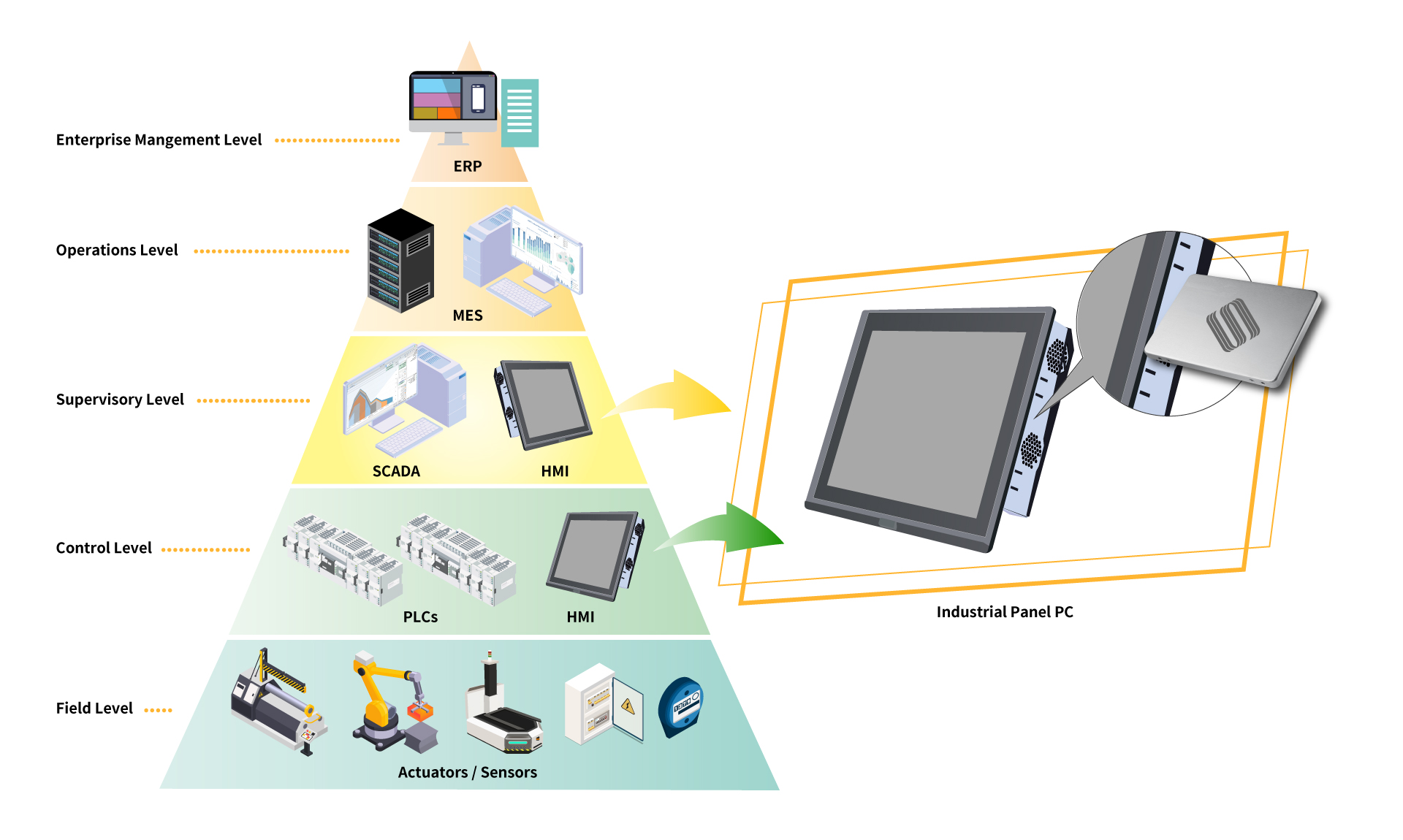

Industrial Panel PCs are the amalgamation of control, computing, and display functions with the PC and the touch panel embedded in the lightweight casing, featuring complete I/O and networking connectivity, or even integrated with card-reader, as well as supporting video-recording functions, as it is a highly integrated HMI (Human Machine Interface) product. The robust and durable design of industrial panel PCs, along with their high-performance computing ability, are instrumental in effectively increasing productivity, as they are widely used in areas of industrial automation, smart factories, medicine, defense, self-service terminals, transportation, telecommunication, utility, and so forth.

As opposed to commercial tablet PCs, most industrial panel PCs are of fanless design and have complete tight-seal casing structures. Having low power-consumption CPU processor, as well as configured internal cooling fins and active cooling design are very important for applications in low-noise and high dust-level environments. As the application environment for industrial panel PCs is harsh, it usually requires waterproof, damp-proof, dust-proof, anti-vibration, anti-shock, extreme voltage resistance functions, so in terms of the external structure, the casing material would feature high-strength engineering-grade plastic materials complemented by high-buffer rubber materials, or lightweight and high-strength alloy-metal materials, to increase protective grade to ensure proper functioning in harsh industrial environments.

Usually, industrial panel PCs would feature multiple ports such as RS232, RS422, RS485, COM, HDMI, VGA, USB, and so forth to access transmitted data and support all types of peripheral equipment and control devices, hence, exhibiting excellent expansion and convenient capability. Industrial panel PCs can be customized to satisfy customer needs such as wide operating temperature support, high IP protective grade, UPS, touchscreen glove support, daylight reading support, and so forth.

Panel PC in Hierarchy Level of Industrial Automation

Industrial panel PCs featuring SSDs can increase PC power-up speed, response speed, and operational stability. As there are no mechanical components and fans within SSDs, there is a zero-decibel environment throughout its operation, which perfectly fulfills the requirement for industrial panel PCs to operate in a low noise-level environment. As there is no mechanical moving parts in SSDs which read/write NAND through control chipset, there is no risk of mechanical failure, collision, shock, and vibration, as SSDs usually operate in high-speed movement, or even flopping or tilting circumstances, which makes them ideal for applications in harsh environment.

The industrial-grade SSDs produced by Solid State Storage Technology Corporation can meet the requirements of industrial applications, as they all pass the industry-standard operating-temperature compliance tests before leaving the factory to ensure their normal functioning within the temperature range of industrial application scenarios without any component damage, data loss, and read-write abnormality, and so forth. The industrial-grade SSDs also pass the extreme voltage stress test, as well as comply with the Anti-Vibration standard of the US military standard, MIL-STD-810G, and Anti-Shock standard of the US military standard, MIL-STD-202G and MIL-STD-883.

Successful Case

SATA and PCIe® NVMeTM M.2 2280 SSDs produced by Solid State Storage Technology Corporation have been widely featured in the HMI industrial panel PCs in many of the world’s top manufacturers’ plants.

SSD Model: CV8 / CVB / CL1 Series SSD

NVMe™ SSD

512GB / 1024GB / 2048GB / 4096GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen5 x4

Sequential Read: UP to 14,000 MB/s

Sequential Write: UP to 12,000 MB/s

SATA SSD

128GB / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 500 MB/s

Sequential Write: UP to 260 MB/s

SATA SSD

128GB / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 500 MB/s

Sequential Write: UP to 260 MB/s

SATA SSD

40GB / 80GB / 128GB / 160GB / 256GB / 320GB / 640GB

NAND Flash: 3D pSLC(TLC)

Interface: SATA 3 (6Gb/s)

Sequential Read: Up to 550 MB/s

Sequential Write: Up to 510 MB/s

SATA SSD

40GB / 80GB / 160GB / 320GB / 640GB

NAND Flash: 3D pSLC(TLC)

Interface: SATA 3 (6Gb/s)

Sequential Read: Up to 550 MB/s

Sequential Write: Up to 510 MB/s

SATA SSD

40GB / 80GB / 160GB / 256GB / 320GB / 640GB

NAND Flash: 3D pSLC(TLC)

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

120GB / 128GB / 256GB / 480GB / 512GB / 960GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

NVMe™ SSD

80GB / 160GB / 320GB

NAND Flash: 3D pSLC(TLC)

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3700 MB/s

Sequential Write: UP to 2600 MB/s

NVMe™ SSD

40GB / 80GB / 160GB / 320GB / 640GB /1280GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

40GB / 80GB / 160GB / 320GB / 640GB /1280GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

80GB / 160GB / 320GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3,500 MB/s

Sequential Write: UP to 2,100 MB/s

NVMe™ SSD

128GB / 256GB / 512GB / 1024GB / 2048GB /4096GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

128GB / 256GB / 512GB / 1024GB / 2048GB /4096GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 6,800 MB/s

Sequential Write: UP to 4,800 MB/s

NVMe™ SSD

240GB / 256GB /480GB/ 512GB / 960GB/ 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3,700 MB/s

Sequential Write: UP to 2,600 MB/s

NVMe™ SSD

256GB / 512GB / 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3,700 MB/s

Sequential Write: UP to 2,600 MB/s

NVMe™ SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 2,000 MB/s

Sequential Write: UP to 1,100 MB/s

NVMe™ SSD

128GB / 256GB / 512GB/ 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 2,000 MB/s

Sequential Write: UP to 1,100 MB/s

NVMe™ SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 3,700 MB/s

Sequential Write: UP to 2,600 MB/s

NVMe™ SSD

256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 6,000 MB/s

Sequential Write: UP to 5,300 MB/s

NVMe™ SSD

256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 6,000 MB/s

Sequential Write: UP to 5,300 MB/s

SATA SSD

128GB / 256GB / 512GB / 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 450 MB/s

SATA SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 450 MB/s

NVMe™ SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 2,000 MB/s

Sequential Write: UP to 1,100 MB/s

NVMe™ SSD

256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: 6,000 MB/s

Sequential Write: 5,300 MB/s

SATA

128GB / 256GB / 512GB / 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128GB / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128G / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

__24C15hqqtC.png)

__24C15wOdCC.png)

__24C05XQ2my.jpg)

__24C05fplcZ.png)

__24C05vgHYC.png)