Five Essentials You Can’t Ignore for Industrial PC SSDs

Why do Industrial PCs need industrial-grade SSDs?

In factory automation, smart manufacturing, traffic monitoring, and embedded systems, SSDs face long duty cycles, wide temperature swings, vibration/dust, frequent writes, and occasional power loss. Selecting SSDs built for industrial use strengthens system stability, data safety, and service life.How to choose an industrial-grade SSD

Selection is never just about capacity and speed. You must also evaluate endurance, operating environment, data integrity, and long-term supply.

1.Wide-temperature design for harsh environments

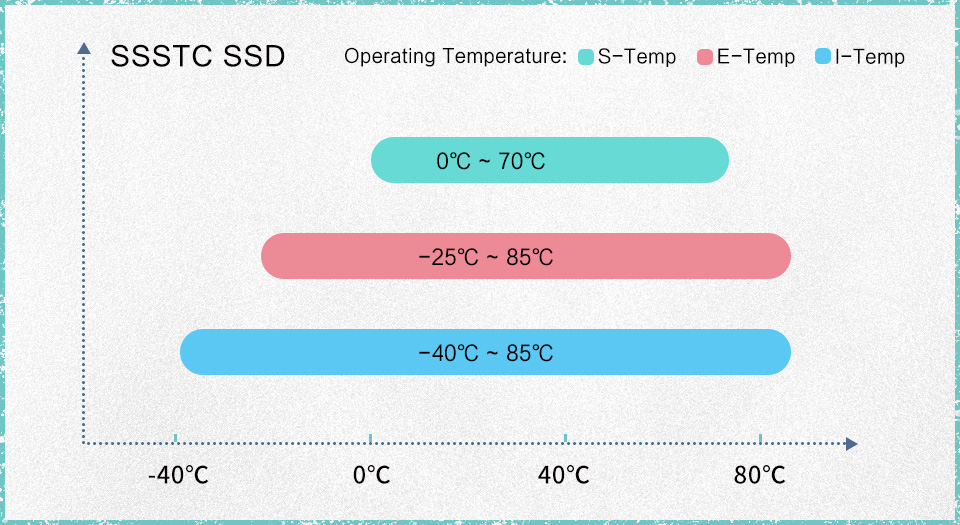

Industrial sites often face extreme temperature swings—outdoor traffic devices, control cabinets, and high-temperature production lines. If the SSD cannot withstand such variations, systems may become unstable or fail to boot. SSSTC industrial SSDs offer multiple operating temperature classes to meet different use cases:

-

Standard Temperature (S-Temp): 0 °C to 70 °C or 0 °C to 85 °C — for indoor and temperature-controlled environments.

-

Extended Temperature (E-Temp): −25 °C to 85 °C — for semi-outdoor or ventilated cabinets that need better low-temp tolerance without full wide-temp spec.

-

Industrial/Wide Temperature (I-Temp): −40 °C to 85 °C — for extreme cold and heat.

Choose the temperature class that best fits your scenario and TCO. SSSTC industrial SSDs pass rigorous extreme-temperature tests to ensure stable operation under rapid temperature changes, safeguarding continuous system uptime.

2. High-endurance design for long-hour, heavy-duty operation

Industrial PCs often run continuously. In scenarios like real-time video logging, equipment logs, and live data acquisition, write frequency far exceeds consumer use. Insufficient write endurance risks premature wear and unplanned downtime.

SSSTC solutions for high endurance include:

-

pSLC mode: Operates TLC NAND in pseudo-SLC mode to raise P/E endurance by 10× or more.

-

Higher DWPD tiers: 1–3 DWPD options for frequent-write applications to ensure long-term stability.

-

Industrial-grade NAND selection: Tightly screened components to reduce bit-error rates and boost overall reliability.

3.Reliable data integrity and error correction

Industrial systems serve mission-critical tasks—automation control, sensor analytics, and event logging. Storage errors can cause production anomalies, misjudgments, or system failures.

SSSTC industrial SSDs implement multi-layer data protection to ensure stability and accuracy of critical data:

-

End-to-End Data Path Protection (E2E): Consistency checks across the entire path from host to NAND to prevent transmission errors.

-

LDPC ECC: Strong error-correction capability to lower bit-error rates and improve read/write reliability.

-

Built-in OP (Over-Provisioning): Reserved NAND capacity to optimize block management, reduce write amplification, minimize wear, and extend SSD lifespan.

4.PLP (Power-Loss Protection) for data safety

While PLP is common in enterprise SSDs, it is equally critical for industrial use—energy infrastructure, industrial gateways, and traffic systems demand strict data consistency and system reliability.

SSSTC industrial SSDs provide multiple PLP mechanisms to strengthen protection during power anomalies:

-

HW PLP: On-board hold-up capacitors supply short-term power so the SSD can complete the last write and protect user data and the FTL mapping table.

-

FW PLP: Firmware coordinates write timing and cache handling to proactively commit critical data when power irregularities are detected.

-

PLN (Power-Loss Notification): Supports host-side early warning so the SSD can flush caches and finish writes before power is lost, reducing data-loss risk.

These PLP options address different protection levels and design constraints. SSSTC can recommend the most suitable PLP type for your application to balance stability and cost.

5. Firmware customization and long-term supply for smooth deployment

Industrial PC lifecycles are long and demand consistency. Any change in SSD components or firmware can trigger compatibility issues or re-validation burdens.

SSSTC supports industrial deployment with:

-

Fixed Bill of Materials (BOM): Locked component versions for product consistency.

-

Firmware customization: Parameter tuning, security/encryption features, and command-set support tailored to your application.

-

Long-term availability: Supply aligned to your product lifecycle to keep the original design in stable mass production.

CA8 M.2 2280

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen5 x4

Sequential Read: UP to 14,000 MB/s

Sequential Write: UP to 12,000 MB/s

Conclusion: Choosing right matters more than choosing fast

Under harsh environments and long-term loads, industrial requirements far exceed consumer specs. Selecting the right industrial SSD means evaluating temperature range, endurance, data integrity, firmware stability, long-term supply—and whether PLP is required. Combining in-house R&D with KIOXIA flash technology, SSSTC delivers high-stability, high-endurance, and highly flexible storage solutions for industrial customers worldwide.

-

SSSTC SATA SSD

Widely used in rugged computers, laptops, servers, edge servers, video surveillance systems, and enterprise-level storage solutions, they offer stable and dependable data storage. -

SSSTC NVMe™ SSD

With high-speed transfer and low latency, it's used in data centers, cloud services, big data, gaming, and graphics, enhancing system performance and speed.

__24C05D67dI.webp)

__24C15hqqtC.png)

__24C15wOdCC.png)

__24C05XQ2my.jpg)

__24C05fplcZ.png)

__24C05vgHYC.png)