Solid State Storage Industrial Grade Wide Temperature SSD Solutions

Application / Workloads

Rugged Computers

In-Vehicle Computers

Surveillance Systems

Fleet Management Systems

Designed for Rugged Environments

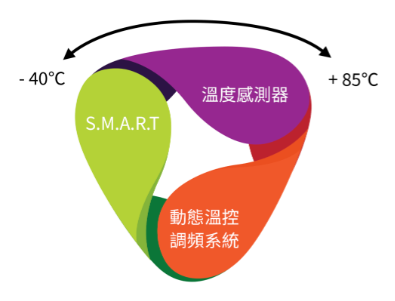

Our industrial grade SSDs offer an automatic temperature control function. The built-in temperature sensor together with a dynamic thermal throttling system ensures the SSDs’ temperature is within a safe range. This overheating protection mechanism guarantees data integrity, equipment safety and promotes stable operation over long periods of time, thereby extending the service life of SSDs.

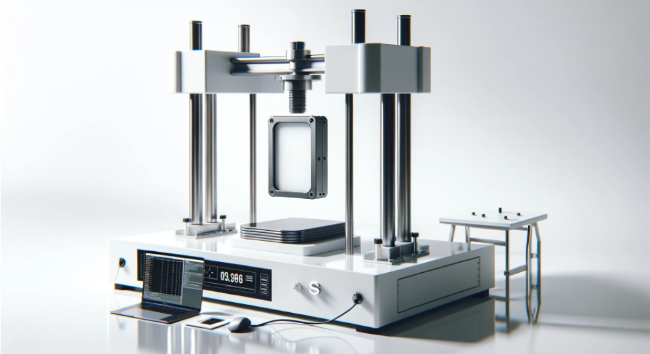

Solid State Storage designs four main exclusive test items specifically for wide temperature SSDs in two aspects namely harsh environment and product reliability tests.

Temperature Operational (Temp OP) Test

- nsure the SSDs perform at optima level without causing any component damage, read/write and comparison errors

- Verify that the wide temperature SSD can operate smoothly under varied conditions

Thermal Profile

Daily Life

DET (FC/PC/PM) Test

1. Read Write test on FC:drive is still able to read and write normally in four extreme states.

2.Power Cycle test on FC:tests the power reboot functionality under four extreme states

3.Power Management test on FC:tests the wake-up functionality from sleep/energy-saving states in four extreme states.

Designed with Anti-Vibration & Anti-Shock

We test SSDs for anti-vibration and anti-shock coefficients under both operational and non-operational states. Under the operational state, we deploy the Burn-in 8.0 testing software, for at least 30 minutes. The SSD is tested in a simulated high-temperature environment to ensure normal performance levels without causing any hardware damage.

Anti-Vibration

Anti-Vibration

Anti-Shock

Anti-Shock

>Non-operation1500G/0.5ms

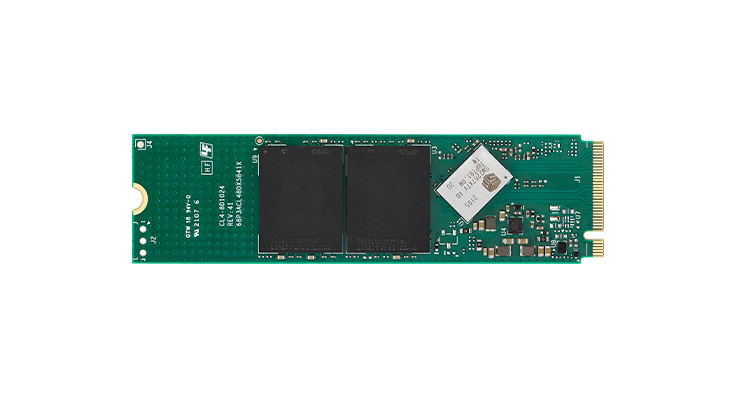

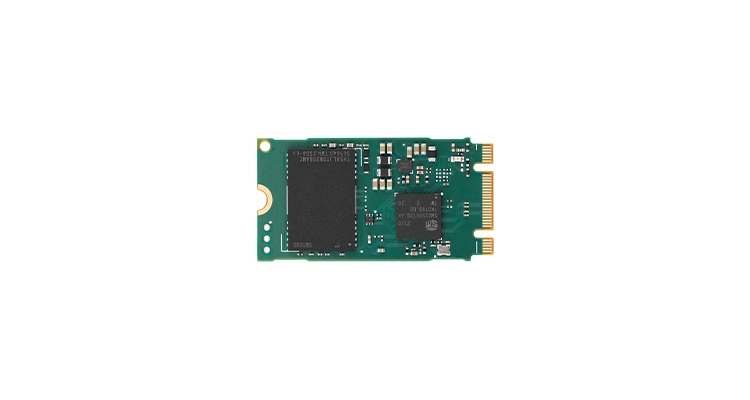

NVMe™ SSD

256GB / 512GB / 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3,700 MB/s

Sequential Write: UP to 2,600 MB/s

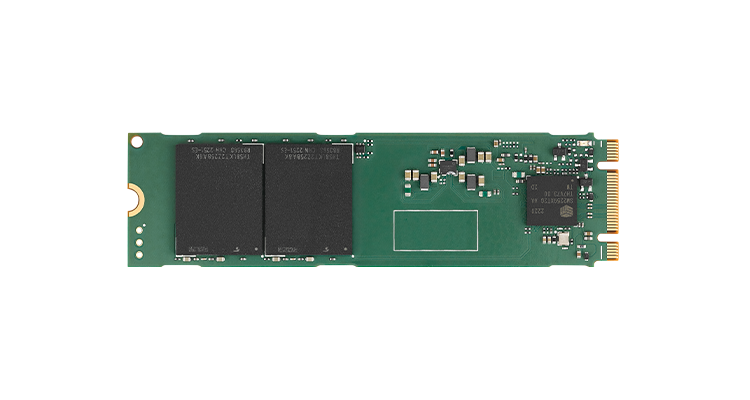

SATA SSD

128G / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128G / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128G / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

__24C15hqqtC.png)

__24C15wOdCC.png)

__24C05XQ2my.jpg)

__24C05fplcZ.png)

__24C05vgHYC.png)